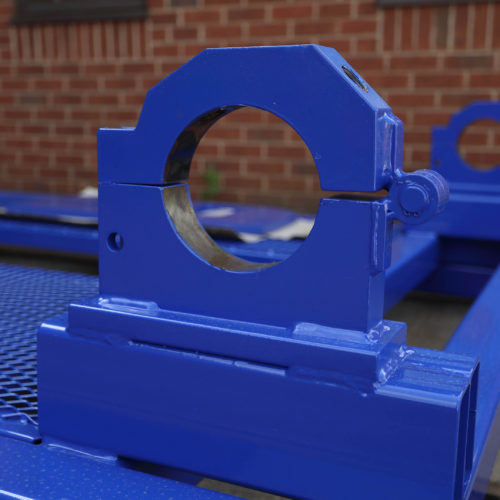

TBS Engineering is a world-leading manufacturer of the automation plant required for the production of lead-based batteries, primarily for automotive and UPS applications. It wanted a reliable, flexible supplier of the frames required to help deliver fully automated, safe and cost-effective battery manufacture assembly lines for a range of customers.

Batteries are an integral part of the world’s critical infrastructure, playing an essential role in everything from energy, transport and logistics, through to manufacturing, communications and storage. TBS Engineering relies on being able to source the high-quality, reliable fabrications to ensure its customers can keep the ‘wheels’ of its infrastructure turning.

“We first began working with TBS Engineering in [XXX], successfully delivering the technology needed for their battery manufacturing machinery,” says [name] [title].

“We’ve maintained that relationship with them ever since, working with them to ensure the continued evolution of the frames that are needed. The lead battery manufacturing process needs to be highly-automated and the operations kept as safe as possible, and we proud to be part of TBS Engineering’s journey towards ‘automating tomorrow’.

Client quote (to be agreed)

“T Booth Engineering very quickly understood our requirements and have always demonstrated a commitment to quality and service.

“This is why we have worked with them for more the XX years – we know we can rely on them to deliver what’s required, on schedule and on budget.” XX TBS Engineering.